High power insert loads are manufactured from RS-4200CHP ceramic high power materials capable of continuous operation at temperatures in excess of 1000°C. RS-4200CHP exhibits outstanding outgassing characteristics measured at 500°C. This material is ideal for use in space appications.*

High power insert loads are manufactured from RS-4200CHP ceramic high power materials capable of continuous operation at temperatures in excess of 1000°C. RS-4200CHP exhibits outstanding outgassing characteristics measured at 500°C. This material is ideal for use in space appications.*

High power insert loads are available in a variety of configurations. These loads can be supplied with tapped holes for mounting or can be expoxied into the waveguide section.

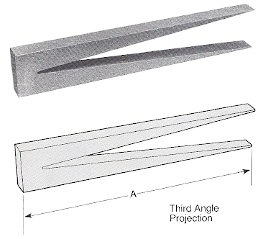

Resin Systems high power spear insert loads are manufactured from RS-4200CHP and fired at 1300°C which assures stable electrical characteristics through the most stringent military environmental operating or storage specifications. The heavy-walled spear insert load is designed for high power applications where length versus power handling capability is critical.

Single Tapered Spear – High Power Insert Loads

| CATALOG NUMBER | DESIGN WR NO. | ELECTRONAUTIC REF. (NO.) | FREQ (GHz) | A MAX (IN.) | POWER (WATTS) | POWER PK. (KW) | VSWR |

| STS-0160HP | 430 | – | 1.7-2.6 | 12.50 | 1600 | 1300 | 1.10 |

| STS-0240HP | 340 | – | 2.25-2.65 | 12.00 | 1400 | 1100 | 1.10 |

| STS-0280HP | 284 | S-8B | 2.60-3.95 | 10.50 | 1200 | 950 | 1.10 |

| STS-0340HP | 229 | 229-WB | 3.30-4.90 | 9.25 | 1000 | 800 | 1.10 |

| STS-0370HP | 187 | C-7B | 3.95-5.85 | 7.875 | 750 | 750 | 1.07 |

| STS-0400HP | 159 | 159-WB | 4.9-7.05 | 7.625 | 625 | 625 | 1.06 |

| STS-0430HP | 137 | XB-WB | 5.85-8.20 | 7.25 | 500 | 400 | 1.05 |

| STS-0490HP | 112 | XL-12B | 7.05-10.0 | 6.50 | 425 | 400 | 1.07 |

| STS-0550HP | 102 | 102-WB | 7.00-11.0 | 6.00 | 325 | 300 | 1.05 |

| STS-0580HP | 90 | X-WB | 8.2-12.4 | 5.00 | 225 | 225 | 1.10 |

| STS-0700HP | 75 | 75-4WB | 10.0-15.0 | 4.00 | 200 | 200 | 1.07 |

| STS-0730HP | 62 | KU-WB | 12.4-18.0 | 3.00 | 200 | 200 | 1.10 |

| STS-0750HP | 51 | 34152 | 15.0-22.0 | 3.13 | 110 | 110 | 1.10 |

| STS-0760HP | 42 | K-2HB | 18.0-26.5 | 3.25 | 150 | 120 | 1.10 |

| STS-0800HP | 28 | KA-WB | 26.5-40.0 | 3.75 | 75 | 275 | 1.10 |

| STS-0810HP | 28 | KA-1HB | 26.5-40.0 | 2.75 | 50 | 250 | 1.10 |

| STS-0850HP | 22 | Q-WB | 33.0-50.00 | 1.38 | 20 | 20 | 1.07 |

* 24 hr. period @ 125°C, vacuum of 1 x 10-6 torr. Total Weight Loss (TWT) 0.238% Volatile Condensable Materials (VCM) 0.008%